Soon, washing machines all over the world will be churning and bubbling with new SA8™ Concentrated Liquid Laundry Detergent from the Amway Home™ brand (known in some markets as Legacy of Clean™).

But laundry conditions vary widely around the globe: from Europe, where washing machines use a tiny amount of water; to China, where colder water is used; to many markets where the water contains lots of minerals.

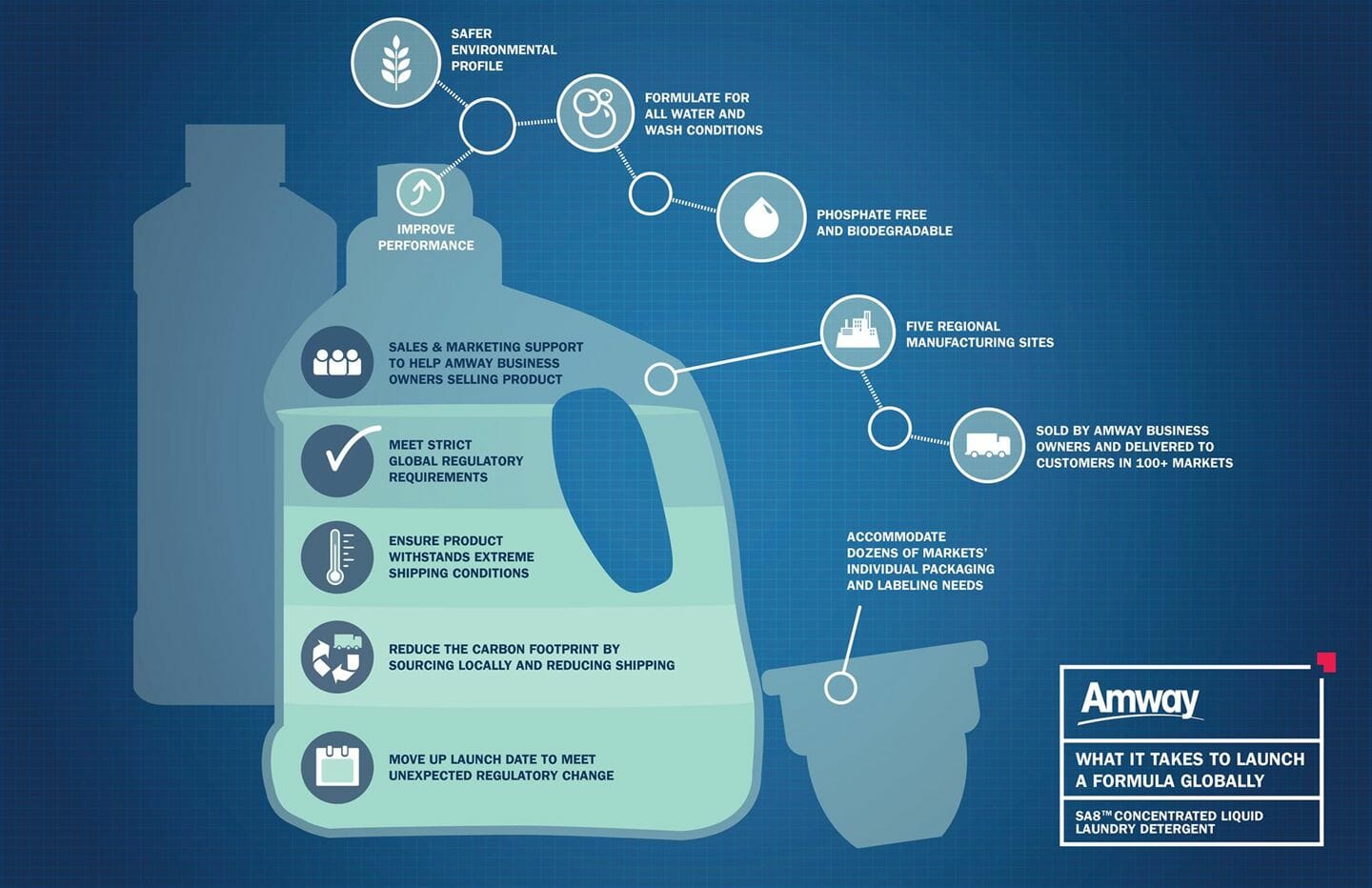

That makes having one global formula challenging, to say the least. Yet Amway customers in those markets, and the rest of the more than 100 countries and territories where Amway products are sold, will be able to buy the same highly effective liquid formula, because the new liquid will be manufactured in all five Amway production sites (U.S., Belgium, China, Vietnam and India), made in the same way by everybody.

That amounts to 4.8 million bottles of this one liquid detergent produced globally a year.

“We’ve never manufactured one single formula in this many global locations,” said Jeff Hazy, senior project manager for the Amway home care team. “This is definitely a first.”

Launching the new global formula has been quite the journey – one that most Amway Business Owners may never get to fully appreciate.

But that’s just fine with the home care team.

“We’re bringing them a product with improved performance and a better environmental profile. By producing it closer to the end user we are reducing shipping distances, so that’s better for the environment.” – Phil Sliva, senior principal research scientist

“Most of what we do is invisible to our business owners,” said Phil Sliva, senior principal research scientist who created the new formula.

“We’re bringing them a product with improved performance and a better environmental profile,” Sliva said. “By producing it closer to the end user we are reducing shipping distances, so that’s better for the environment.

“Our goal is to add as much value as we can without having to pass on a big cost increase.”

Let’s take a behind-the-scenes look at the intricate journey of this unprecedented global launch.

What will it take?

The plan was ambitious: enhance the performance of SA8™ Concentrated Liquid Laundry Detergent, the workhorse of many laundry rooms around the globe. Give it an even better environmental profile. And to streamline and improve production efficiency, make a single formula in all five Amway SA8™ liquid manufacturing locations, to sell in every market where Amway products are sold.

Like any Amway product, there’s a detailed plan, and a flow chart that maps out the “Idea To Market” process, the journey every Amway product takes, encompassing everything from concept to market rollouts.

Feasibility is an early consideration: what will be needed to commercialize this product? How and where will we manufacture it?

Teams are always asking, “How can we get products to Amway customers quicker and more efficiently?”

Can the product withstand days inside a shipping truck where temperatures hit 50 degrees C (120 degrees F)? What about packaging? It can’t leak…what will happen if the product ships upside down?

Behind every stage of these projects is a key concept: agility. Teams are always asking, “How can we get products to Amway customers quicker and more efficiently?”

Formulating improvements

Formulating improvements

Amway scientists have a lot to consider when formulating laundry detergent. For one thing, washing machines differ from country to country. Washing conditions, such as water temperature, water mineral content (“hardness”) and the length of washer cycles, vary greatly.

The ingredients – including fragrances, which can be especially challenging – have to pass regulatory muster in more than 100 countries and territories, each with its own complicated rules and regulations.

“Our Amway Business Owners want to take this into customers’ homes and show people why it’s better. We have to make sure it is.” – Phil Sliva

Scientist Phil Sliva’s task: create a formula that cleans better, smells nice, is safer for families and the environment, and meets every market’s requirements.

“Our Amway Business Owners want to take this into customers’ homes and show people why it’s better,” Sliva says. “We have to make sure it is.”

Global supply, local sourcing

The new formula needed some ingredients that Amway wasn’t currently using in all its manufacturing locations.

That’s where Brian Turner came in. As lead sourcing manager, he scours the globe for ingredients. His challenge: work with local and global suppliers to locally supply as many of the raw materials as possible in manufacturing locations, to avoid as much long-distance shipping as possible.

“We want to get the best cost for the consumer as well as the best quality, and be good stewards of the environment, so we want to ship fewer things long distances.” – Brian Turner, lead sourcing manager

“This is truly a global product, but we’re sourcing material locally now whenever possible,” Turner said. “We want to get the best cost for the consumer as well as the best quality, and be good stewards of the environment, so we want to ship fewer things long distances.”

He had to make sure there is “supply security” – multiple sources for raw materials, so if something happens to block a supplier in one location, he can get it from another.

Turner talks a lot about how supply chain affects “service level” – making sure the detergent is available when Amway customers want it. Now, it will be, more than ever.

“As Amway demand continues to grow, we are responding with global sourcing in order to efficiently deliver SA8 liquid to customers around the world,” said George Calvert, Ph.D., Amway chief supply chain and R&D officer.

The lead markets weigh in

The lead markets weigh in

Europe, Russia and India — which account for nearly half of all Amway home care sales – had considerable input into the new formula. What would the new SA8™ liquid smell like? What size would the bottles be? What would the label look like? Can we change the bottle cap, so the fill line is easier to read?

Reducing the carbon footprint and using ingredients with improved environmental performance were among the region’s top priorities.

“As Amway demand continues to grow, we are responding with global sourcing in order to efficiently deliver SA8 to customers around the world.” – George Calvert, Ph.D., Amway chief supply chain and R&D officer

“In Europe, eco-friendliness is a big issue,” said Claudia Hape, portfolio manager for home care for the Europe, Russia and India region. “Every time you update a product, it needs to be better ecologically.

“When we begin regional production in Belgium, which is very close to our European and Russian warehouse in the Netherlands, our transportation costs will decrease tremendously,” Hape said. “Our carbon footprint will be much smaller. That’s a big selling point for our business owners.”

Meeting global regulations

Meanwhile, it was Doug Didion’s job to keep track of each country’s regulations for products sold there. It’s a complicated task – and regulations change constantly.

“Europe has one set of regulations, Ukraine and Turkey have their own, the Far East has their own, and so does Thailand,” said Didion, senior regulatory analyst at Amway. “Everybody has their own little take on things.

“We don’t just look at the formula, but also at the packaging, and claims we want to make about the product,” Didion said. “Not all claims can be made in all countries.”

“Never miss a launch date” is the Amway goal

Just when the new formula was nearly complete, came breaking news from Russia.

The Russian Parliament had unexpectedly voted to reduce the allowed amount of an ingredient that keeps liquid detergent fluid in low temperatures, far below any other standards.

“This came out of nowhere,” Jeff Hazy said. “We had four months to respond, and we did it without missing a beat.”

The goal is to keep customers happy by not missing launch dates, and the team was determined to achieve that goal.

What saved the project was the formulator’s foresight. Phil Sliva anticipated regulatory changes could be coming in some markets and his original formula profile eliminated the ingredient. He created and qualified the new SA8™ formula before Russia announced its new requirements.

So the new formula itself would meet the new regulations, but the launch had to be accelerated to make Russia’s deadline – and that required having the supply chain in place ahead of schedule. That kind of change at this stage in the game is seriously challenging and highly unusual. But at Amway, the goal is to keep customers happy by not missing launch dates, and the team was determined to achieve that goal.

They could do that, Hazy said, because of the great working relationship the home care team has, and the tight partnership the team has with the markets.

Round after round of registration

While Europe and Russia love a small carbon footprint, those markets also have the strictest requirements for registration, the process of making sure a product meets all of a country’s regulatory requirements.

Some markets have more rules and take longer to register than others, which is why SA8™ Concentrated Liquid Laundry Detergent is launching at different times in different markets through January 2017.

The process for getting a product registered varies widely from country to country. In Indonesia, for example, Amway might send 20 bottles of liquid to the registration department so they can see if it meets their regulations. That process alone can take more than a year, while other countries might just require an ingredient list to review and approve it quickly.

The marketing equation

The marketing equation

Marketing is a crucial part of the plan: how can Amway best help Amway Business Owners sell SA8™ Concentrated Liquid Laundry Detergent?

That’s where JoJo Conti, global brand manager for home care, takes the lead. She directs creation of the communication plans and materials, from print ads to videos, and designs promotions for the markets and Amway Business Owners to use.

JoJo’s challenge: laundry habits vary widely across Amway markets. The marketing materials must help Amway Business Owners demonstrate the benefits of the new formula to customers who’ve never used SA8 liquid laundry detergent, as well as to fans of the previous SA8 liquid formula.

In Russia, for example, where most people typically use powdered detergents, consumers are uneducated about liquid detergents, Claudia Hape said. So they put a “neck hanger” card (shown) on the bottle that gives an up-close look at the product’s performance claims.

India, where many consumers have no experience with liquid laundry detergents, gets a video explaining the power of the new liquid.

And for Europe, where Amway products are sold in 30 countries and 26 languages, the global brand team created a video that the region adapted and localized in various languages to support their markets (click here for an example).

Hundreds of details, and they all matter

As the project comes together, Toni Rich, product content specialist, ensures the many, many critical details are managed. She collects information from all areas involved to complete the product specifications.

A product manufactured in five countries and sold in 100+ markets needs extra attention to details like:

Packaging: the dimensions of the carton and color of the cap can vary by market.

Label design: one symbol might mean different things in different cultures.

Regulatory requirements: markets have different requirements or preferences on things like “best before” dates and including a manufacturing address on the label.

Rich’s group reviews the details before production trials begin. “I’m a second set of eyes to make sure everything is right, so manufacturing can produce the product correctly,” Rich said.

A truly global launch

Through the tall challenges and unusual hurdles, the team never backed down.

“We were determined, because it’s a win-win-win-win-win for Amway and our Amway Business Owners,” said Phil Sliva.

“SA8™ is one of Amway’s heritage products and the tradition continues with the global launch of the new SA8™ Concentrated Liquid Laundry Detergent,” said Calvert, the supply chain chief. “Our SA8™ Team leveraged the latest in technology to maximize cleaning performance while better protecting the environment for the next SA8™ generation.”

Formulating improvements

Formulating improvements The lead markets weigh in

The lead markets weigh in The marketing equation

The marketing equation